Floating Dock Types Explained

Floating dock systems are available in many different styles, colours and aesthetics, but all of them fit into 1 of 3 floating dock design TYPES:

Each of these floating dock types has distinct design features that create on-water performance. The design type determines Float Profile, Capacity, Durability, and Active Response.

Understanding the capabilities of each floating dock type is key to choosing the right floating dock system for your waterfront.

Floating

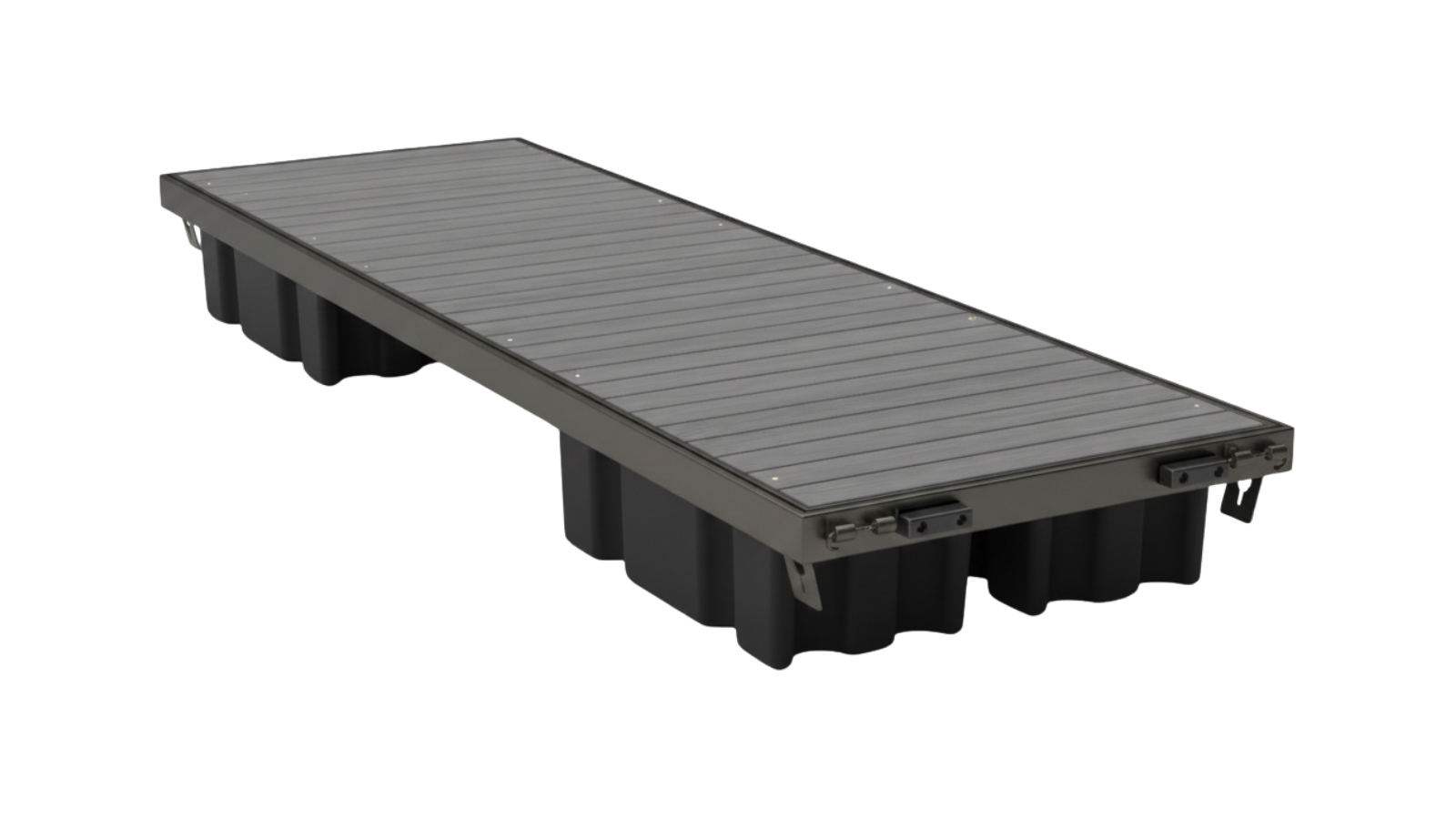

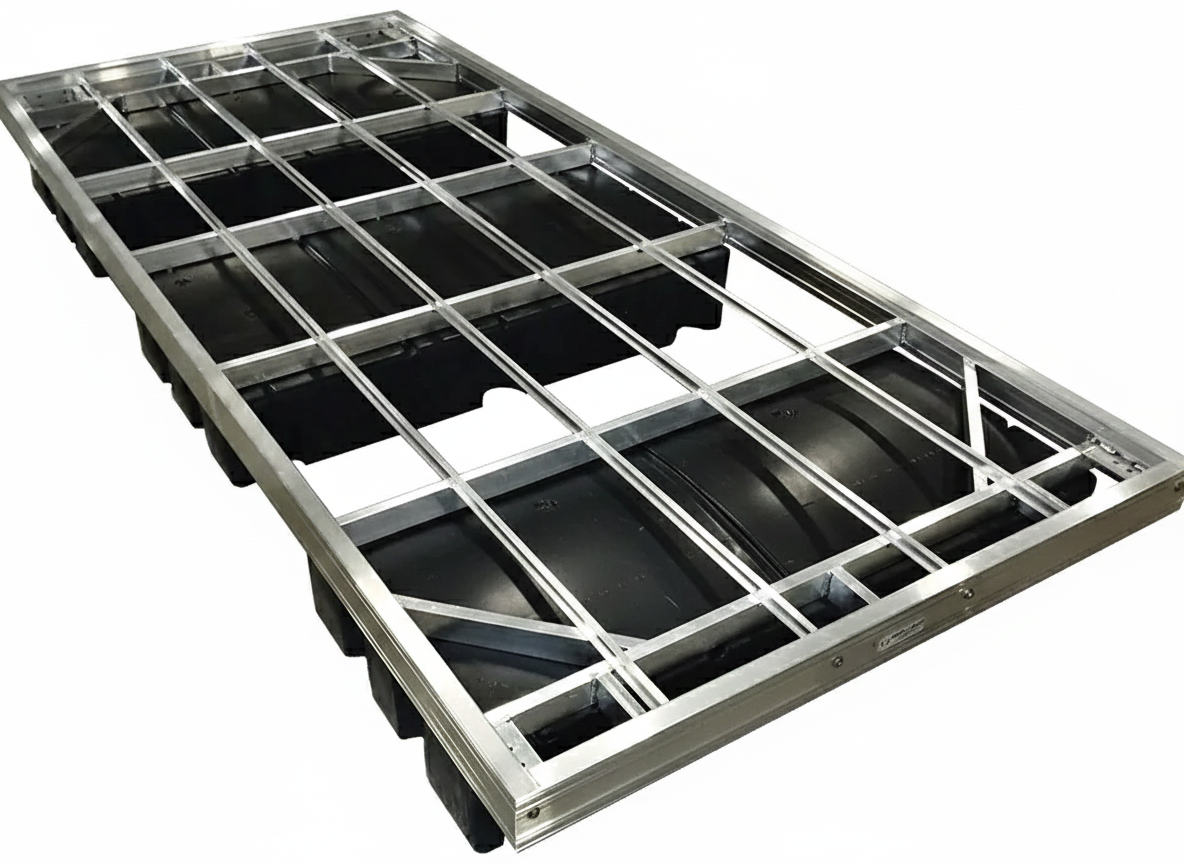

Pontoon Floating Docks - previously referred to as ‘barrel float docks’ are the oldest floating dock design type. It’s design is consistently enlisted to tackle jobs requiring immense float capacity. Today’s Pontoon (external float) docks are substantially more advanced, stable, and vary considerably in design.

Pontoon docks are characterized as any floating dock system that features external flotation connected to a frame with a topside platform. While every brand puts their own stamp on this dock type - They all feature a frame and deck supported by large buoyant pontoons.

Pontoon docks float using the upward buoyant force known as Archimedes’ Displacement Principle. Pontoon docks establish their water stance by displacing its matching weight (or more) down into the water as the water pushes up with equal pressure to situate the dock.

Pontoon dock floats come in varied design shapes and buoyancy capacity. The shape, size and structure of the frame all effect the dock’s water stance.

Pontoon Docks have the most available options when it comes to the design and material options.

DECKING

The topside platforms can be made with Wood, Composite, Aluminum, Fibreglass PVC, and even cement! Within these categories there are even more options to put your personal touch on a dock system.

PONTOONS (Floats)

The Floats are generally constructed with High Density Polyethylene (HDPE), although this varies by the quality of the dock system. The pontoon floats usually have Air, foam material like EPS (Expanded Polystyrene), or a combination of them.

FRAME

Pontoon floating dock frames are most often built using Marine-Grade Aluminum, Treated lumber, Steel, and Composite. Aluminum frames are the most common because they have a high strength-to-weight ratio.

Pontoon style (external float) floating docks bring customization and strength to your waterfront. This style, formerly known for instability and tipping, is quite the opposite with modern designs. These dock systems boast superior float capacity and rigid topside stability.

Pontoon Docks (external flotation) Advantages

ROUGH WATER DURABILITY

External float docks provide additional buoyancy, helping the dock stay steady in areas with waves, wakes, or other dynamic water conditions.HIGH FLOAT CAPACITY

With large external flotation pontoons, this dock can support heavier boats and equipment, making it a great choice for people with larger vessels or multiple watercraft.CUSTOMIZATION

Pontoon docks offer the most customization options for materials. Decking, Frames and Floats are available to suit the majority of aesthetic preferences.

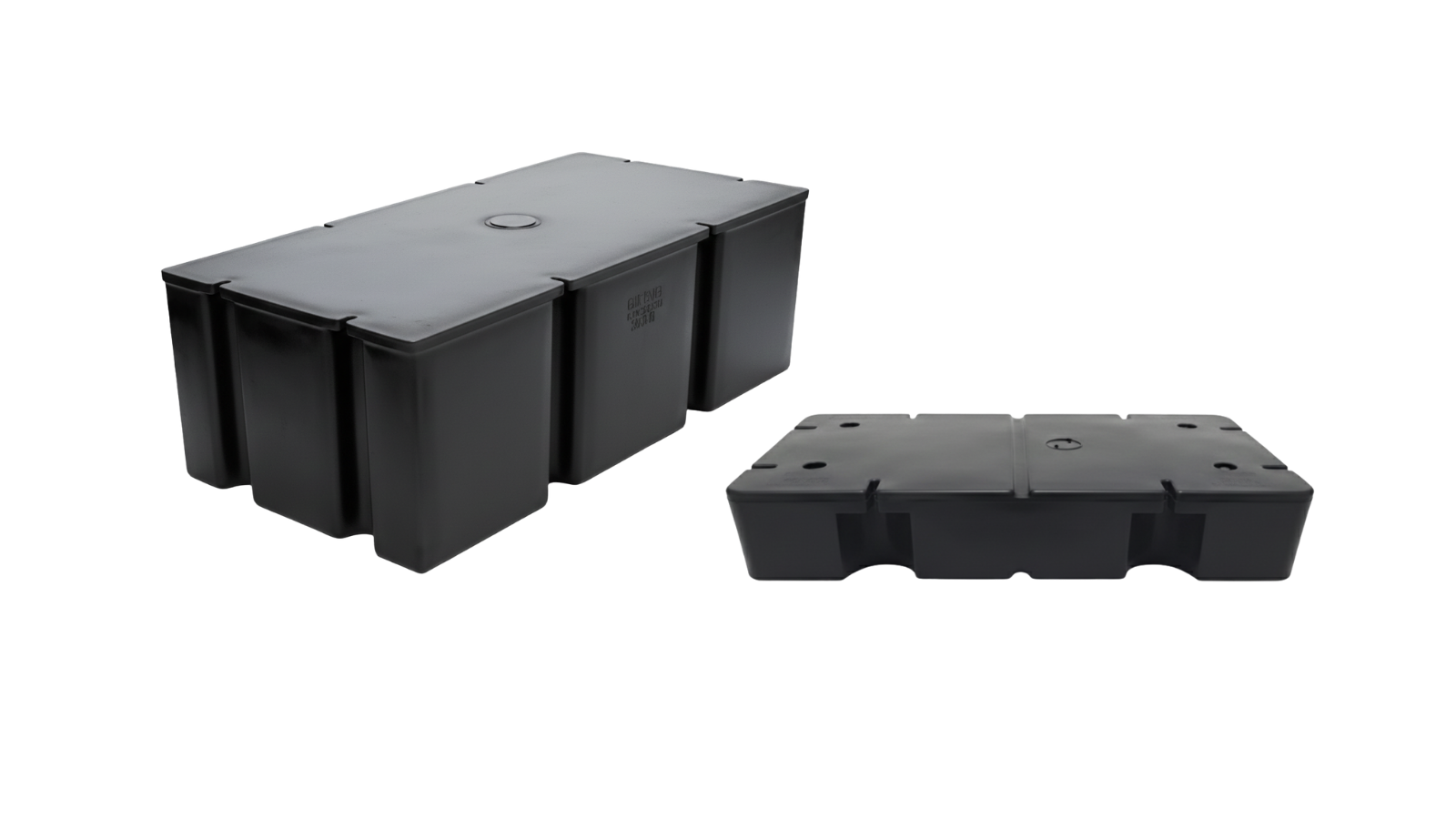

Single-Mould or self-contained floating docks are characterized as a sealed dock section that combines the dock structure and flotation into a single unit.

Made of roto-molded polyethylene, these self-contained structures are manufactured as one seamless mould. This construction method eliminates seams, a potential point of weakness in other designs.

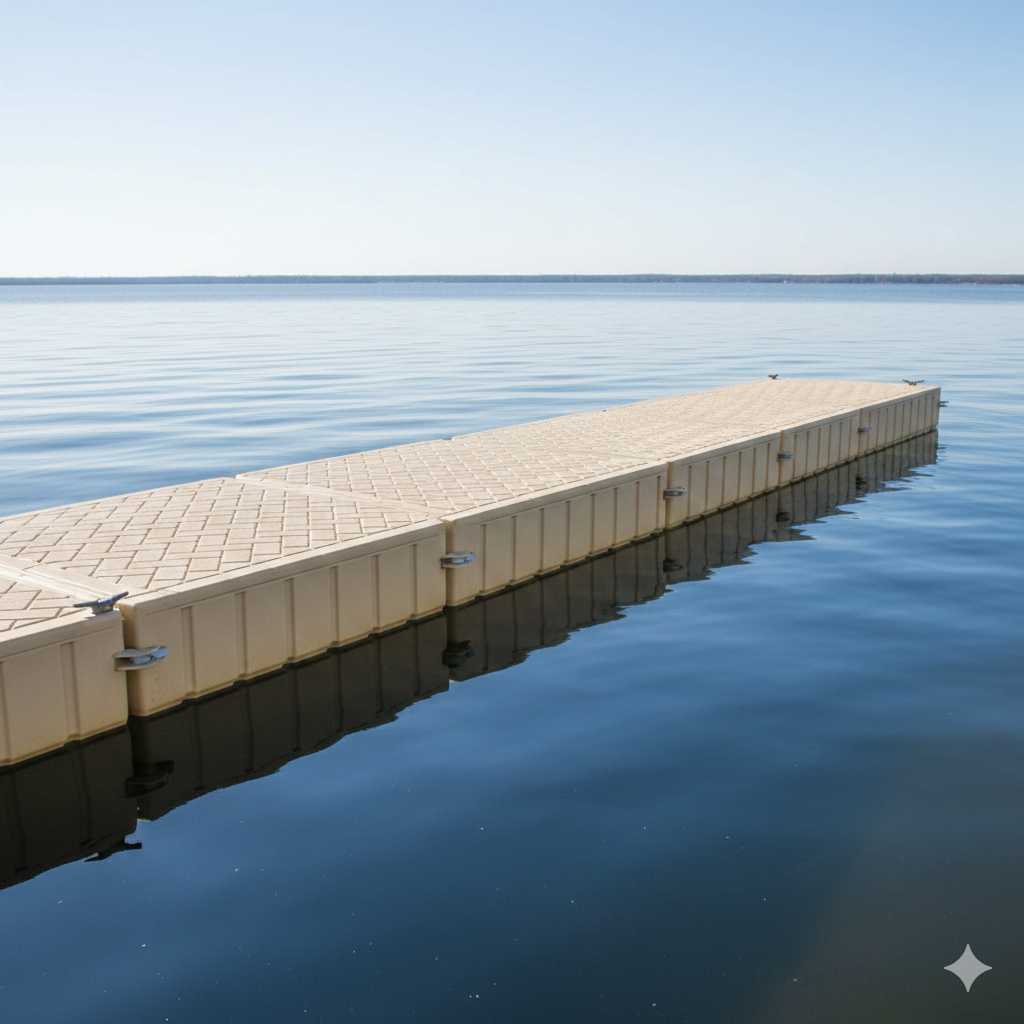

Also known as integrated flotation, these docks feature a streamlined structure with virtually no maintenance, light weight - high float capacity and scalable design.

Integrated single-mould docks are designed to use Hydro-static Surface Pressure flotation. Unlike docks that focus on displacement, these docks leverage a chamber or cavity design on the underside of the dock which traps air creating suction pressure. Similar to submerging a glass into water it becomes tougher to pull the glass out because of the opposing force created by trapped air; this is hydro-static surface pressure flotation.

This type of flotation enables an incredibly stable water stance for the dock. The larger the platform the stronger the overall connection to the water.

Single-mould (integrated flotation) docks are made using Polyethylene, specifically LLPE (Linear Low-Density Polyethylene). This is sprayed during the roto-mold process to construct a self-contained hollow section with trapped air inside. While most Single-mould docks use trapped air as flotation, there are some that also use foam inserts and sprays like EPS (Expandable Polystyrene).

Polyethylene docks are resistant to breakdown and environmental conditions. They offer a high tensile strength and hold up very well against wake impact and weather.

Integrated single-mould docks boast many advantages. The technical flotation and design make these systems a cut above. Platform section options for dimension and shape can make virtually any desired layout.

The perimeter pocket design makes adding dock sections, anchoring systems, accessories, and watercraft dry-docks quick and easy. Dock systems with wake dispersal capability and cavity suction design provide the strongest water stance.

Single-Mould (integrated flotation) Advantages

SEAMLESS CONSTRUCTION

Made from a single piece, these docks offer a unified streamlined look with no seams or connections, making them aesthetically cleaner and less prone to debris buildup.LOAD DISTRIBUTION

The integrated flotation ensures a uniform distribution of weight providing a reliable foundation for standard boating activities even with varying water levels.LOW MAINTENANCE

Because the flotation is built into the structure there are fewer parts to maintain or replace. This reduces overall maintenance and ensures the dock remains functional with minimal effort.EXTENDED LIFESPAN

The single-mould design is resistant to cracking and environmental wear making it a long-term solution for those seeking a more permanent hassle-free dock..

Cube-style docks are built from standardized interlocking cubes that provide independent flotation. Each cube floats separately distributing weight evenly across the entire structure. This design allows the dock to remain stable, even as water levels fluctuate, without the need for additional support. The flexibility of the modular system makes it easy to customize and expand the dock whether you need more space or need to adjust for changing waterfront conditions. This makes cube-style docks an ideal choice for homeowners seeking a stable, adaptable, and low-maintenance solution.

Cube-style docks float efficiently due to their modular design as each individual cube acts as a separate buoyant unit. The cubes interlock tightly allowing for weight to be evenly spread across multiple points. When water levels fluctuate, the dock adjusts naturally because each cube independently maintains buoyancy. This prevents warping or shifting ensuring a stable platform. The standardized design allows for consistent performance as each cube is uniform in size and weight distribution to further reduce the risk of instability or uneven settling.

Floating dock Cubes are most often constructed using HDPE (High Density Polyethylene). They are typically constructed as a seamless single roto-mould unit, however some are two-piece construction.

HDPE is the ideal plastic dock when it comes to salt water environments. HDPE Cube docks are very durable, and resistant to corrosion and breakdown.

Cube Style Dock (Standardized)

SPACE EFFICIENT DESIGN

Cube docks are ideal for smaller or irregular waterfronts. Their compact, modular shape makes them easy to fit into tight spaces without losing functionality.CONFIGURATION FREEDOM

Cube docks are generally 2 ft square (0.19 meters) which allows for dock design layouts that may not be possible with other types of floating dock systems.EASY TO EXPAND OR MOVE

The modular nature of cube docks allows for easy expansion by adding more units or relocating them, which is great for seasonal setups or changing dock configurations.

Floating

Dock

Systems

Takeaways

Floating Dock technology has come a long way, and it continues to make strides to address the toughest on-water challenges.

It’s no longer a question of can a floating dock do this..

.. and more of a, which one is best!