TFR Dictionary

Definitions

float·ing dock

/ˈflōdiNG däk/noun

A Floating Dock (or Dock System) is Defined as:

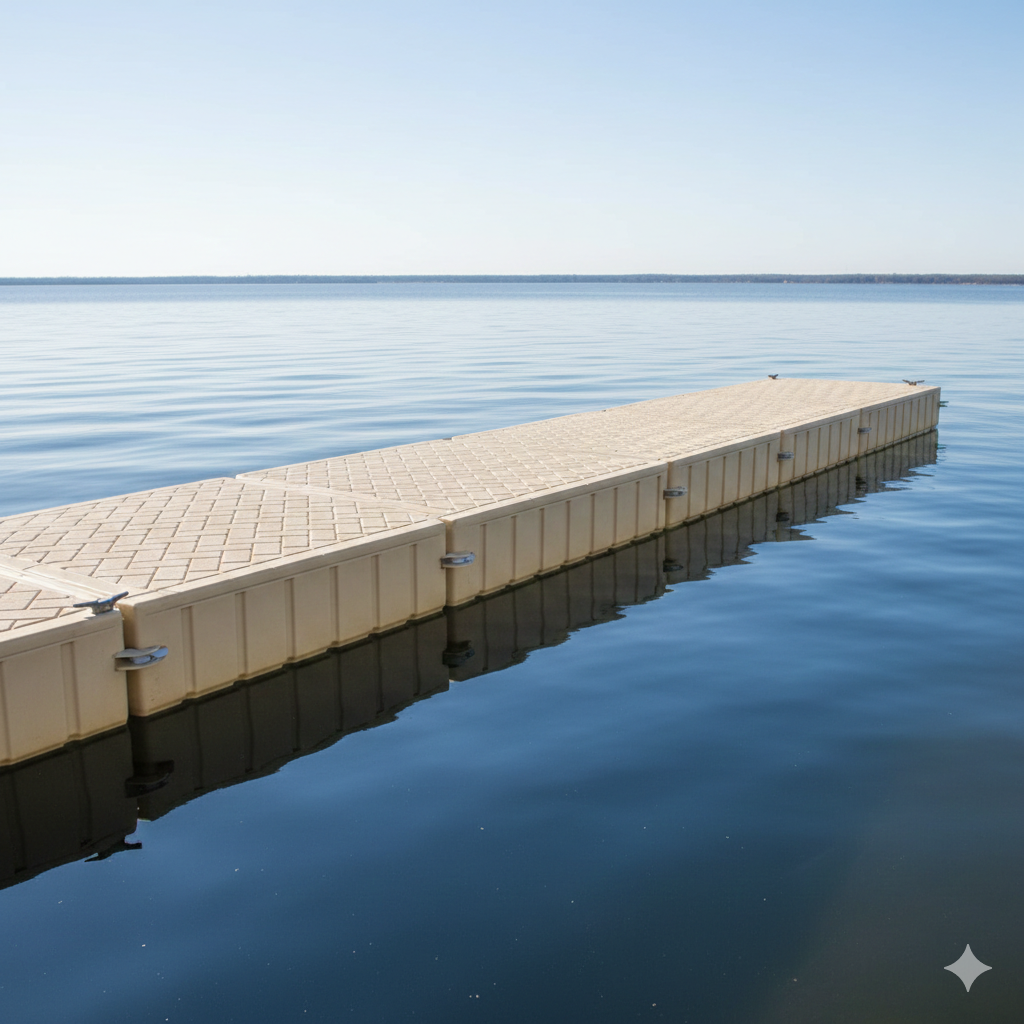

‘A buoyant platform secured to a flexible anchoring system, that allows the dock to rise and fall as water levels change - while maintaining topside stability.’

Floating Docks are Designed to Work with the Environment to Achieve Stability

Floating Dock systems are often still thought of as unstable or flimsy. But, the truth of the matter is, modern polyethylene floating docks perform better in varied environments, and have a longer lifespan than fixed (stationary) docks.

How do they do it?

Like the movement of a skyscraper in high winds, floating docks are made to be sturdy, yet flexible. Tall buildings must sway (however minimally) to avoid damage, floating docks are designed to work in much the same way, they flex to reduce the impact of the water.

While floating dock systems vary significantly by brand and design, they all require these necessary components to perform three essential functions:

Flexible Movement, Water Stance, and Level Adjustment

To do this, floating dock systems need the following:

Reactive Anchoring

Flexible Connectors

Flotation Design

Floating

Floating

Dock

Anchoring

A key feature of Floating Dock Systems is the varied anchoring types that allow for application to virtually any waterfront.

Each anchoring option can be used on its own or in combination with others to maximize security and optimal functionality. This includes standard Pilings (posts), Dead Weights, Stiff Arm Brackets, Hinge Adaptors and Bottomless Stand-off Brackets.

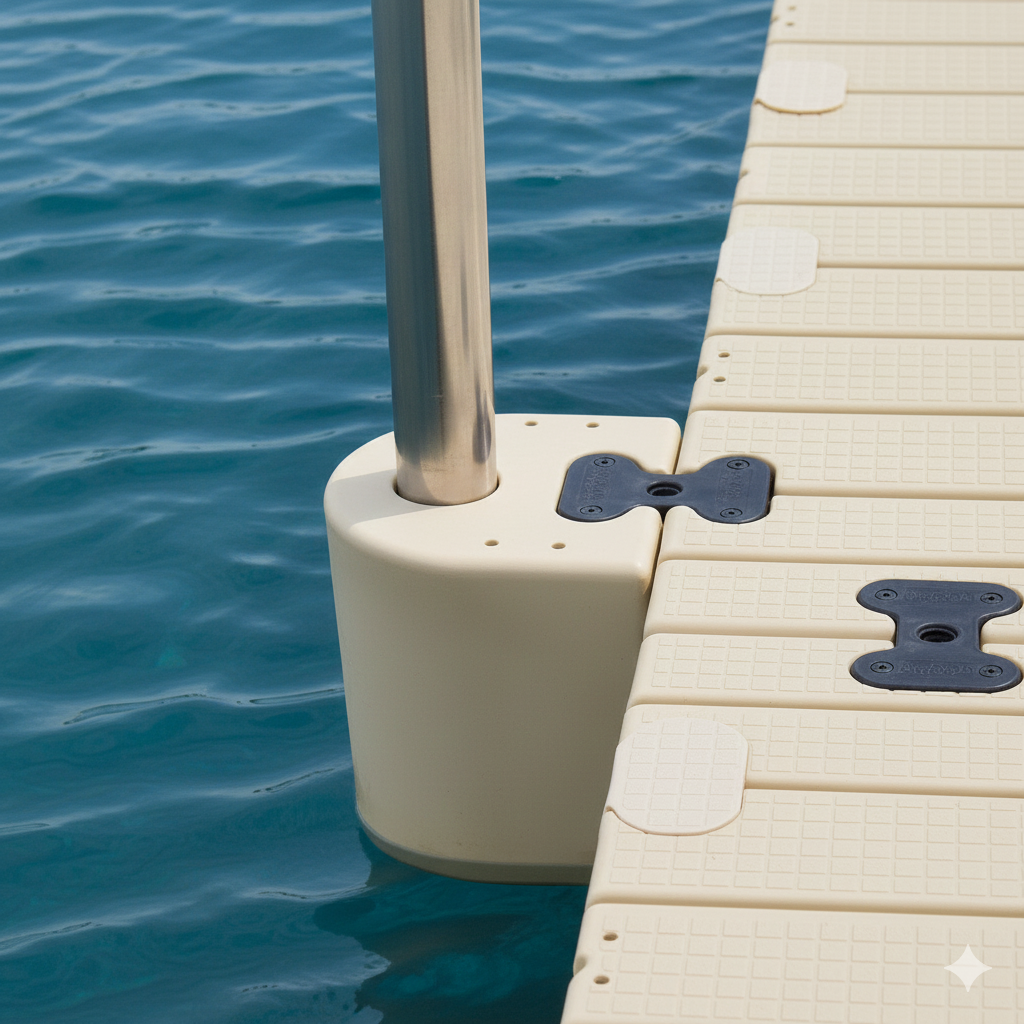

Piling (Post) Anchoring

The most common type of anchoring for floating docks is the Pilings (post) setup. This anchoring option is ideal for most waterfronts without steep drop-offs or inhospitable bottoms. These can be used in depths up to 20 ft (6.1 m).

A Piling (posts) system is the sturdiest floating dock anchor option. Depending on the dock system brand, Posts either connect to the sides along the perimeter of the dock, or via cutout holes (a less used option) in the dock itself, from which the post is dropped through to the bottom.

The post setup typically has 3 pieces: the post/piling, the sheath/bracket, and an auger (screw point) on the bottom of the post to drill into the water bottom.

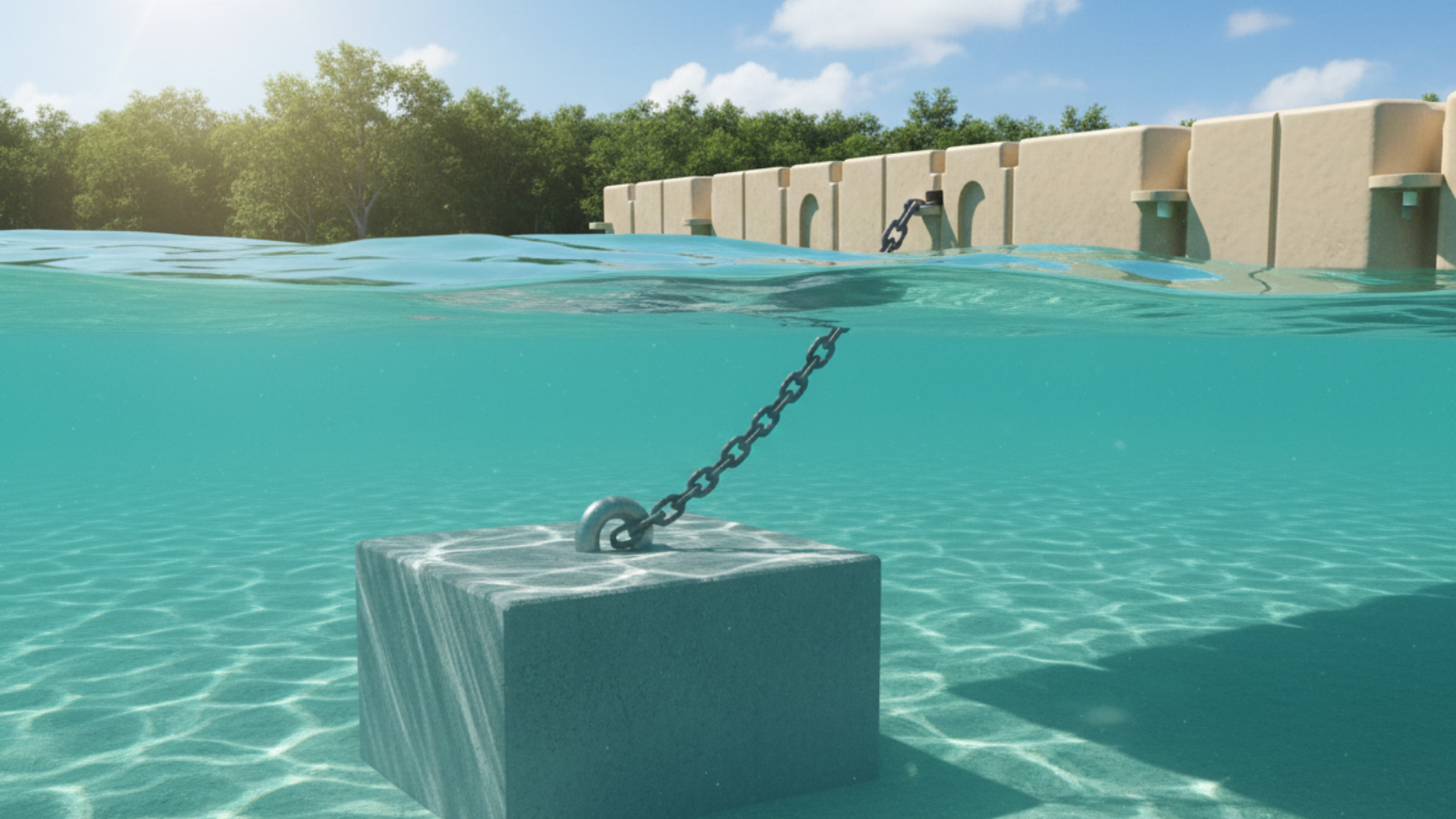

Dead Weight Anchoring

Floating Docks with dead weight anchoring are used for deep water or lake beds with bottom consistency that cannot receive pilings (posts).

Dead weights can also be combined with other anchoring types to adjust for waterfront environments with steep drop-offs. In that case, dead weights can be used at the deep end, while the shore side (shallow portion) can be secured with posts.

Dead weight setups quite often utilize additional anchoring types for additional security and stability. In deep water scenarios, the additional anchoring is most often Stiff-Arm or Bottomless Stand-off brackets close to the shore. Mixing the anchor types for dead weight setups is recommended for extra stability, especially if the dock is receiving watercraft or is in an area with constant winds and movement.

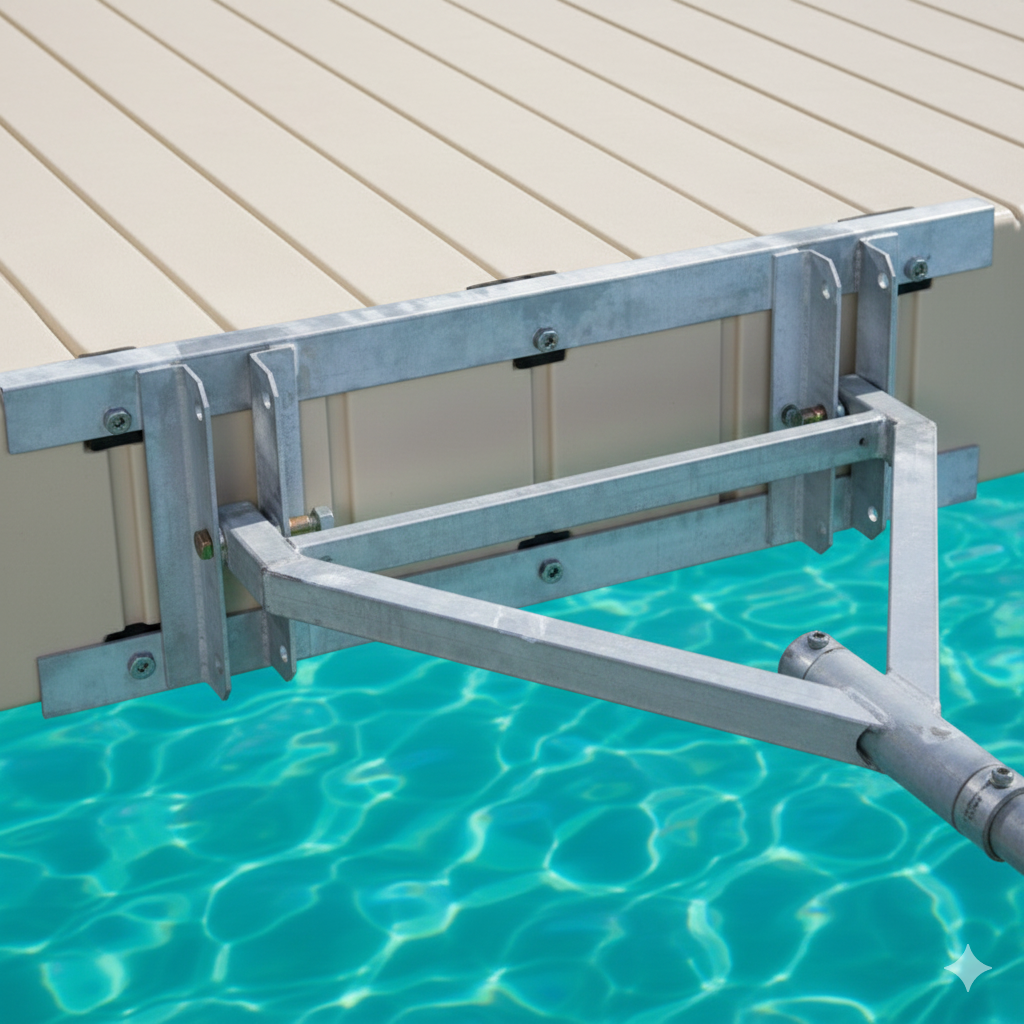

Stiff Arm Anchoring

Floating Dock Stiff-arm brackets are ideal for deep water environments like channels or rivers. When water depth exceeds the dead weight anchoring option, Stiff-arm anchoring fills the gap (literally and figuratively).

Stiff-arm brackets are the ideal choice for temporary or seasonal dock systems. They can be used in conjunction with every other anchoring option to enhance security or connect to an existing dock.

Bottomless Stand-Off Anchoring

Similar to Stiff-arm brackets, the bottomless Stand-off anchoring system is ideal for steep drop-offs and deep water environments. These can be customized and are generally used for less extension into the water, whereas the Stiff-arm brackets are used for longer waterfront gaps.

Stand-off anchoring is frequently used in smaller dock platforms, gangways or PWC/Boat Ports in marinas.

Floating

Dock

Connectors

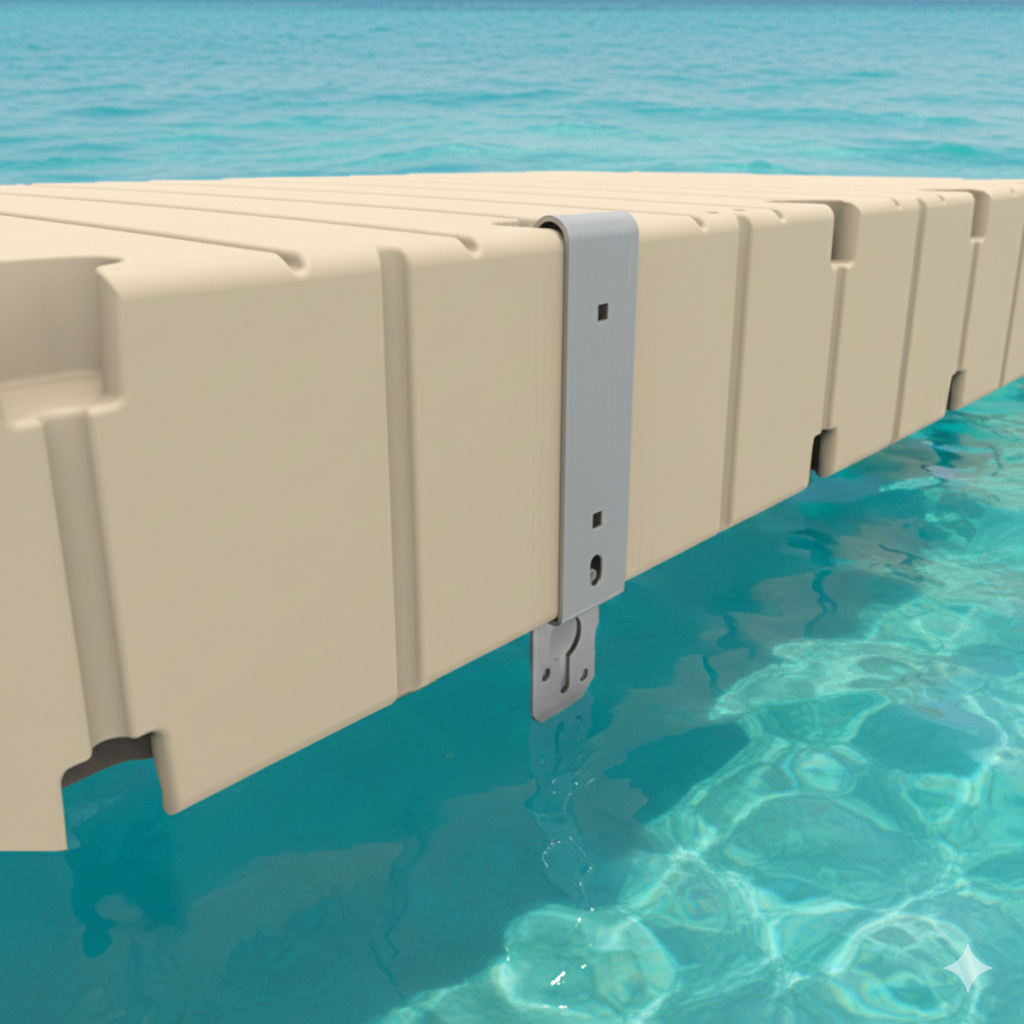

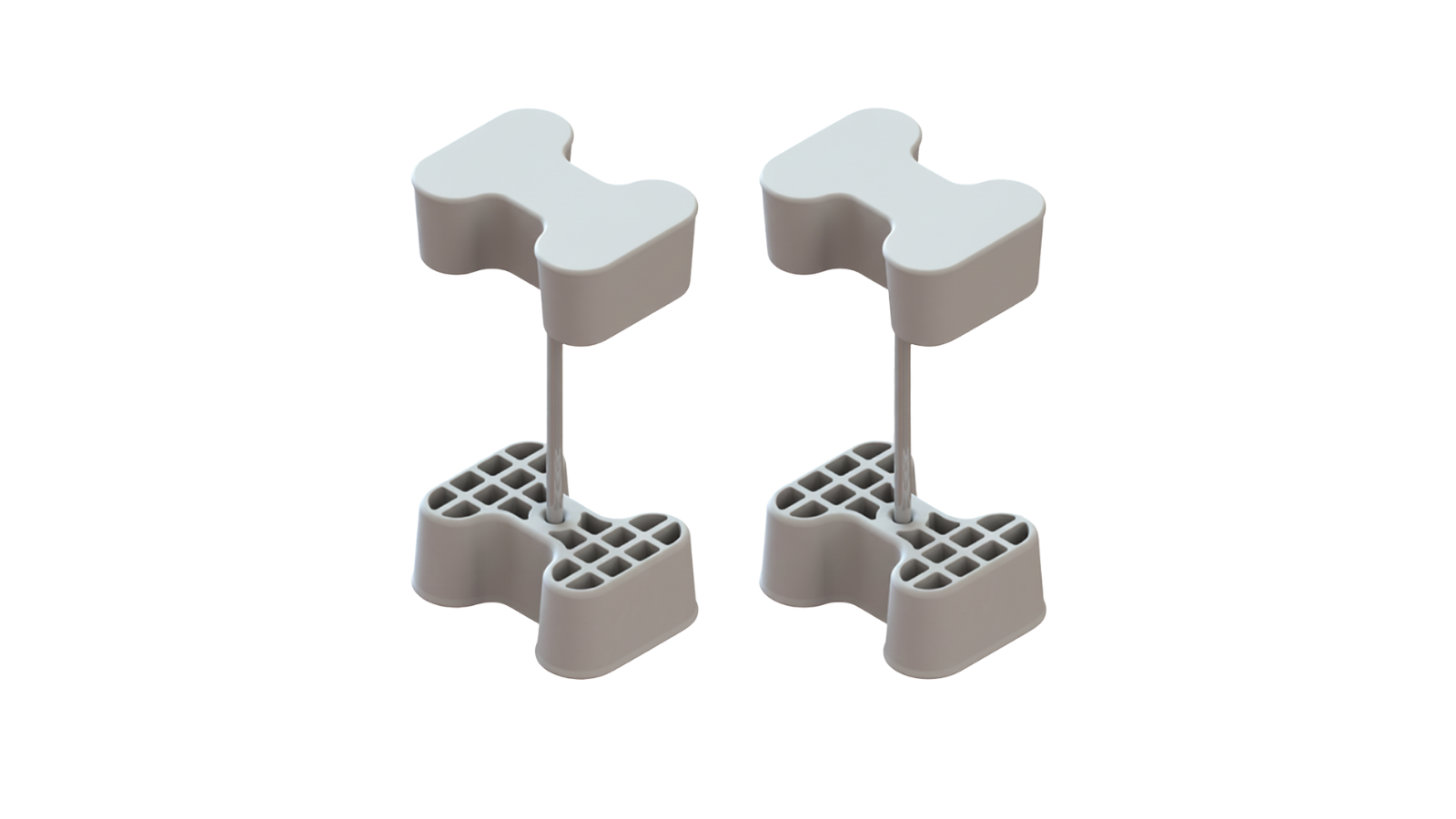

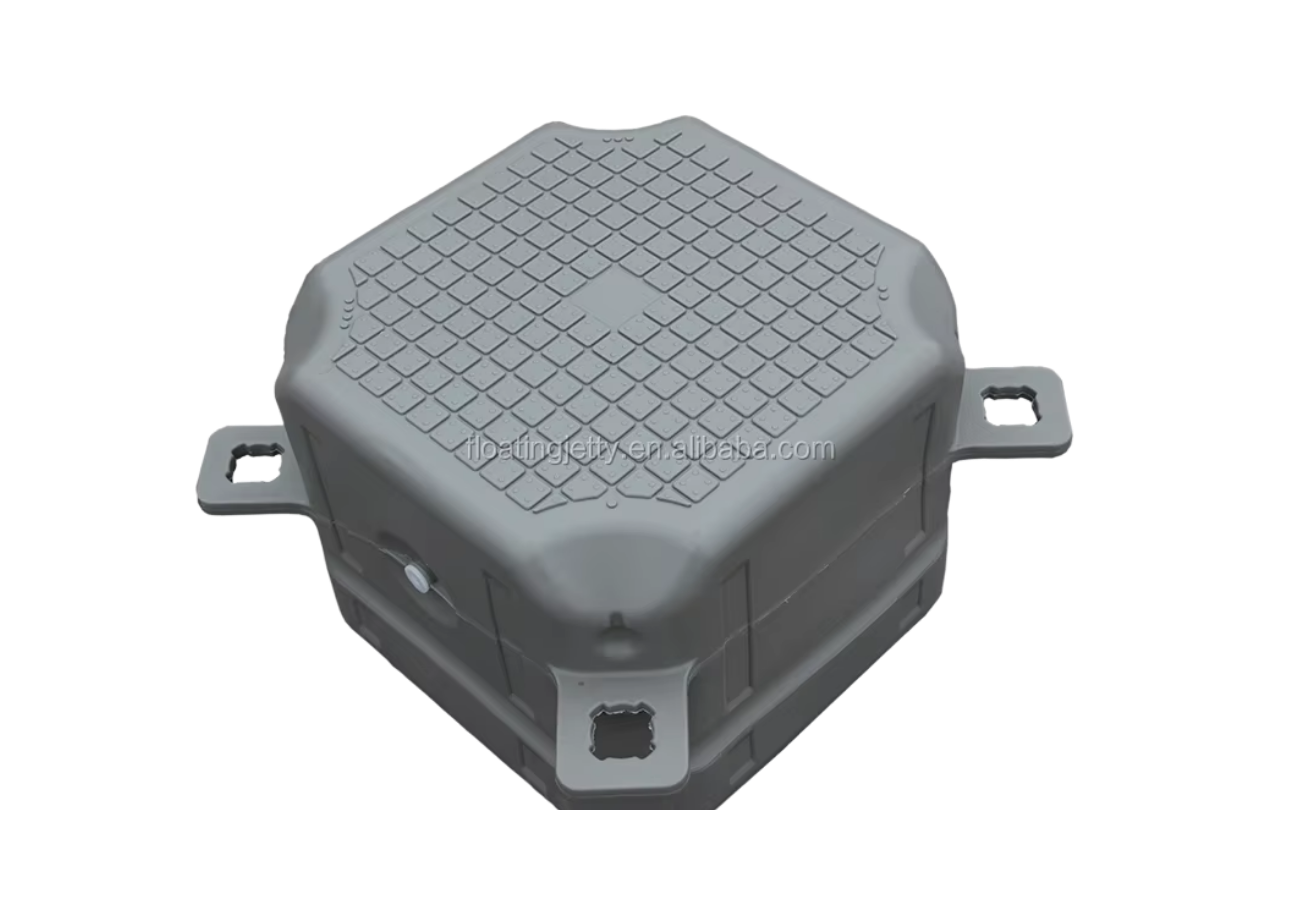

The connectors in floating dock systems have three primary responsibilities, to keep the dock sections securely connected, allow them to move independently, and to absorb or disperse impact from the dock.

Floating dock systems are not designed to simply withstand the force of water like a fixed (stationary docks), they’re purposefully designed to actively protect the dock by absorbing and redistributing it.

Floating Dock Connectors Secure, Flex and Protect

The connectors in floating dock systems are more than the pieces that make your design possible. They are designed to perform 3 jobs simultaneously and on-demand. They must keep the dock sections securely fastened, flex to allow the dock sections to move independently, and intercept and disperse the twisting torque or shock from water movement.

The stability of a floating dock system is entirely dependent on the function of its connectors.

➤ SHOCK ABSORPTION

Floating dock connectors not only affix the docks to each other, they are the protection for the docks themselves. No matter how slow the current or size of a body of water, its movement power should never be underestimated. Watercraft wake, chop, storms and wind, do not take it easy on docks.

The first job of floating dock connectors is to insulate the dock sections from damage, by absorbing and dispersing shock. Each brand and design of floating dock addresses this differently, but the focus remains the same. Floating docks are not designed to withstand currents and chop like stationary docks. Instead, they’re built to absorb and process this pressure to ensure the dock pieces are protected.

➤ PLATFORM SECURITY

Floating dock connectors keep the sections (dock pieces) secured in a platform. A simple job with a not-so-simple design requirement. Floating dock connectors must keep the platform secured as one, while simultaneously allowing each piece to move independently as the water acts upon it. It may sound contradictory, but it makes sense and works!

The Second job of floating dock connectors is to hold the dock’s shape with a connection that still allows each section to operate independently.

➤ FLEXIBLE MOVEMENT

Because floating dock systems are in constant motion, the connectors must be designed for Rigid Flexibility. They must secure the dock sections with enough flex to allow movement yet rigid enough to not be compromised by the water’s impact.

The Third job of floating dock connectors is to maintain the platform’s shape and stance while flexing when required, to allow each section to move with the current as it flows through, under and around the dock.

Floating

Dock

Flotation

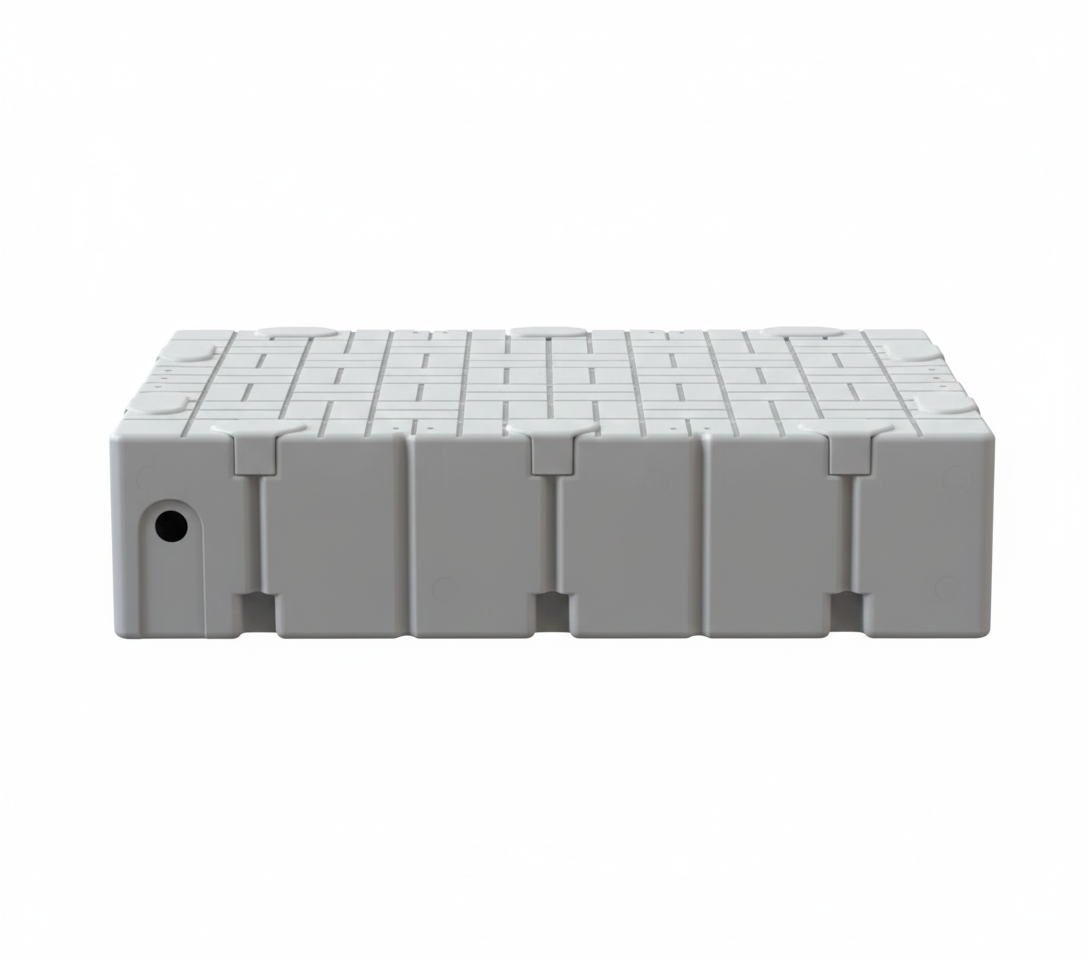

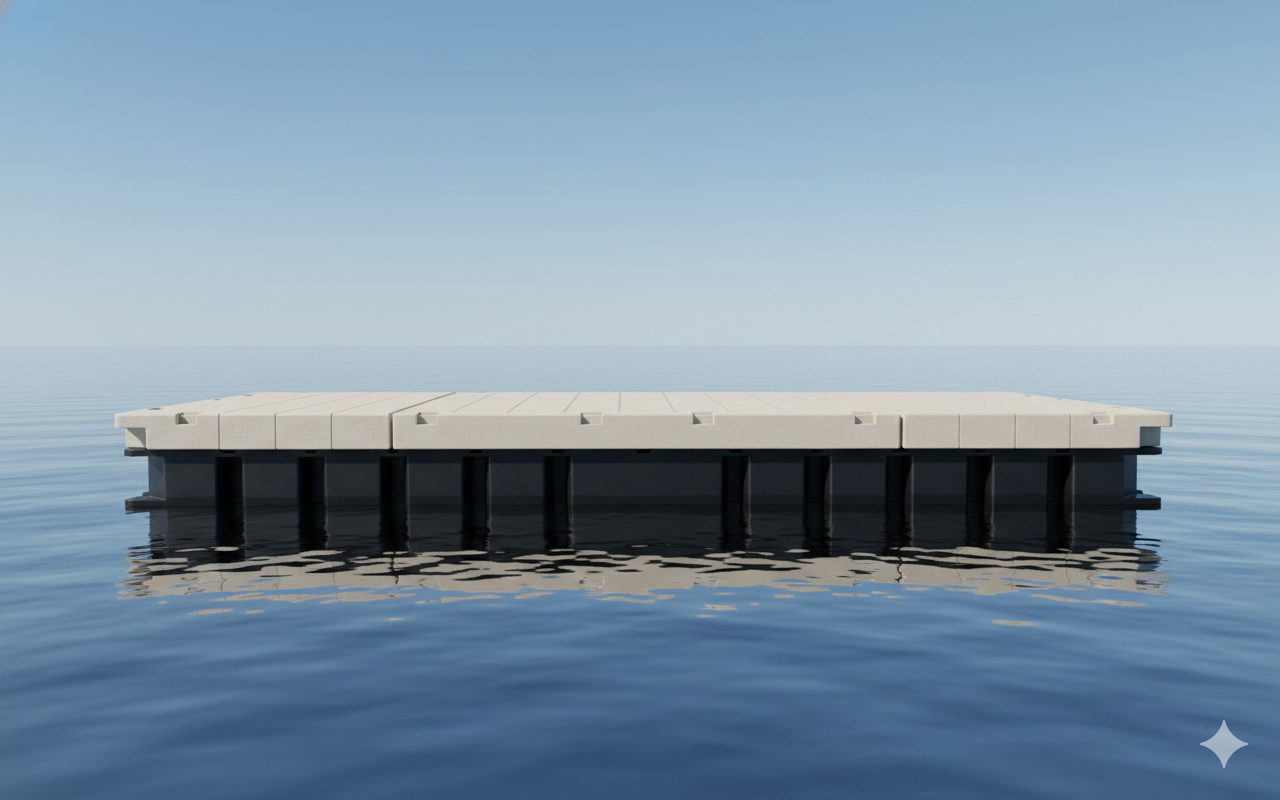

It's a common misconception that Floating Docks simply sit on the surface and float uncontrolled. Modern floating dock systems are designed to actively engage with the water to ensure a steady stance, regardless of the surrounding environment.

Much the same as boats, floating docks are constructed to exist in a constantly moving environment. While stationary docks must use strengthened construction to withstand forces, floating dock design allows the damaging elements to pass by with minimal impact or disruption.

Flotation - How Floating Docks Maintain their Water Stance

Floating docks actively respond in real-time to mitigate impact, adjust level, and maintain position, as conditions change.

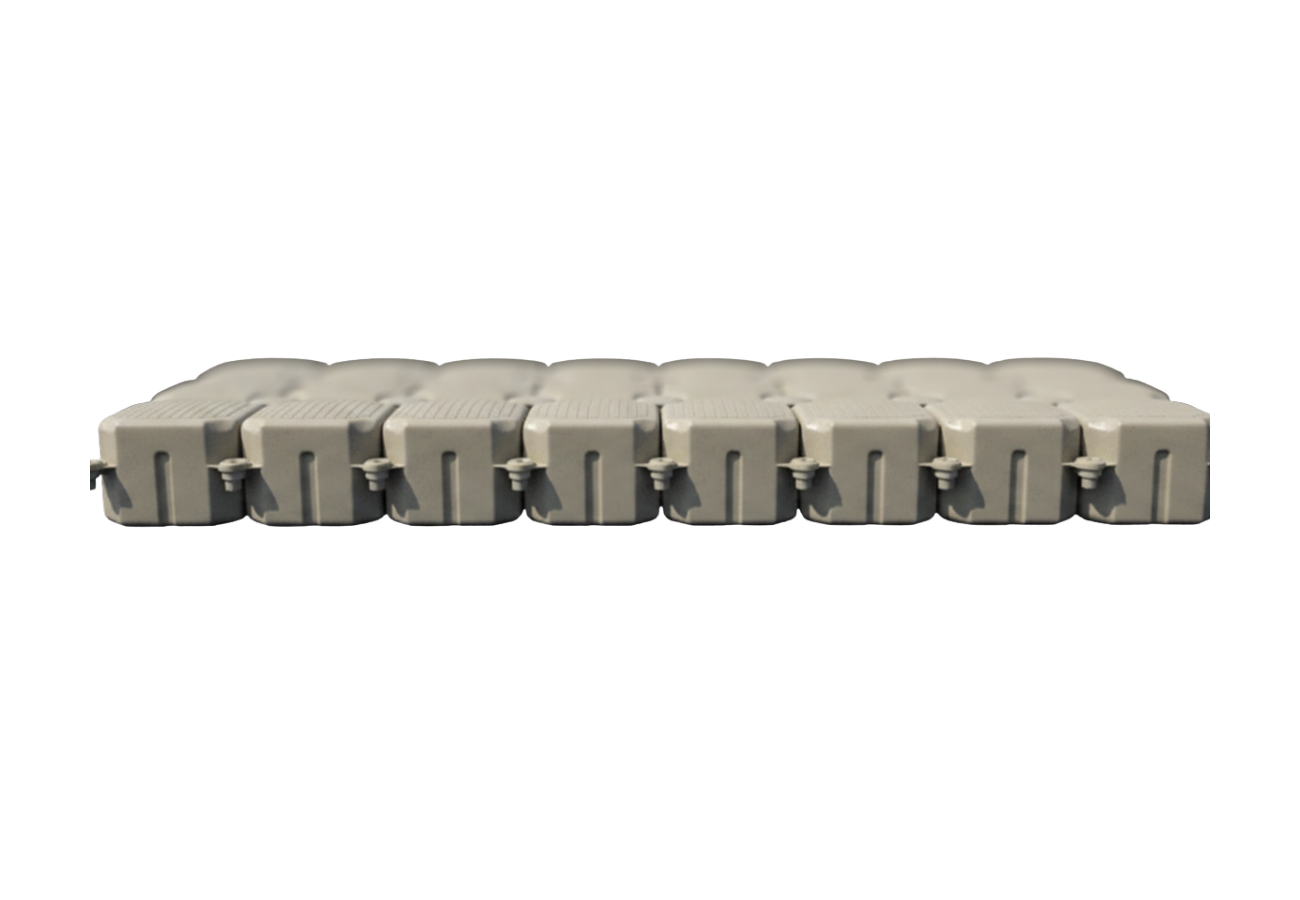

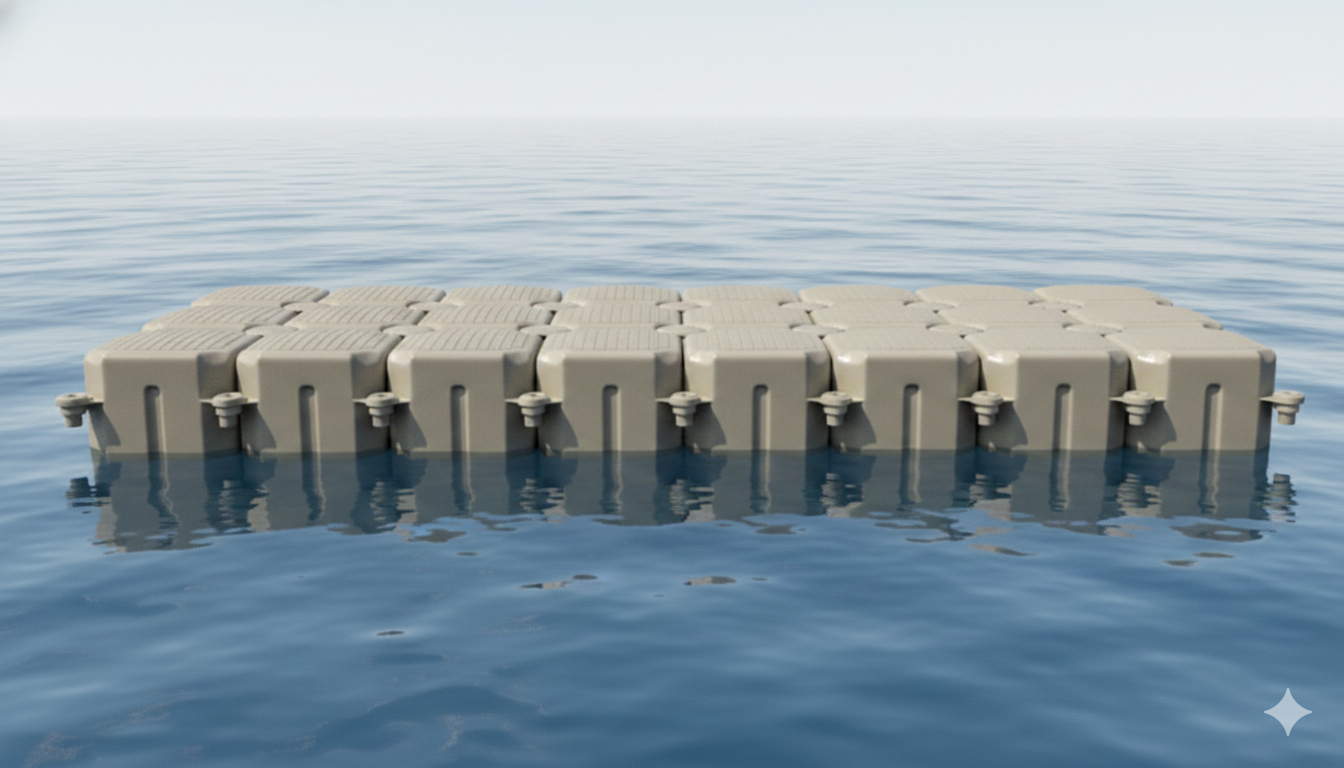

Each floating dock system’s design works to reduce the powerful torquing pressure of swirling water. Component designs like wake-muffling cutouts and water diversion channels reduce shock and enable flexible section movement to protect the dock.

Let’s take a look at how these elements of floating dock design enable flotation dynamics..

Flotation Dynamics: How Do Floating Docks FLOAT?

HYDRO-STATIC SURFACE TENSION

Hydro-static surface tension (or pressure) Is made possible by underside hollow cavities that trap air between the dock and the water surface. This powerful suction force keeps the dock securely positioned beneath the surface.

DISPLACEMENT PRINCIPLE

The Displacement Principle of buoyancy. Stability is achieved when the dock’s weight is displaced by the equivalent amount of water to create an upward force. This upward pressure is what keeps the dock in a stable position.

Flotation Type: Hydro-Static Surface Tension

Flotation Type: Displacement Pressure

➤ Polyethylene Floating Docks - Flotation Material

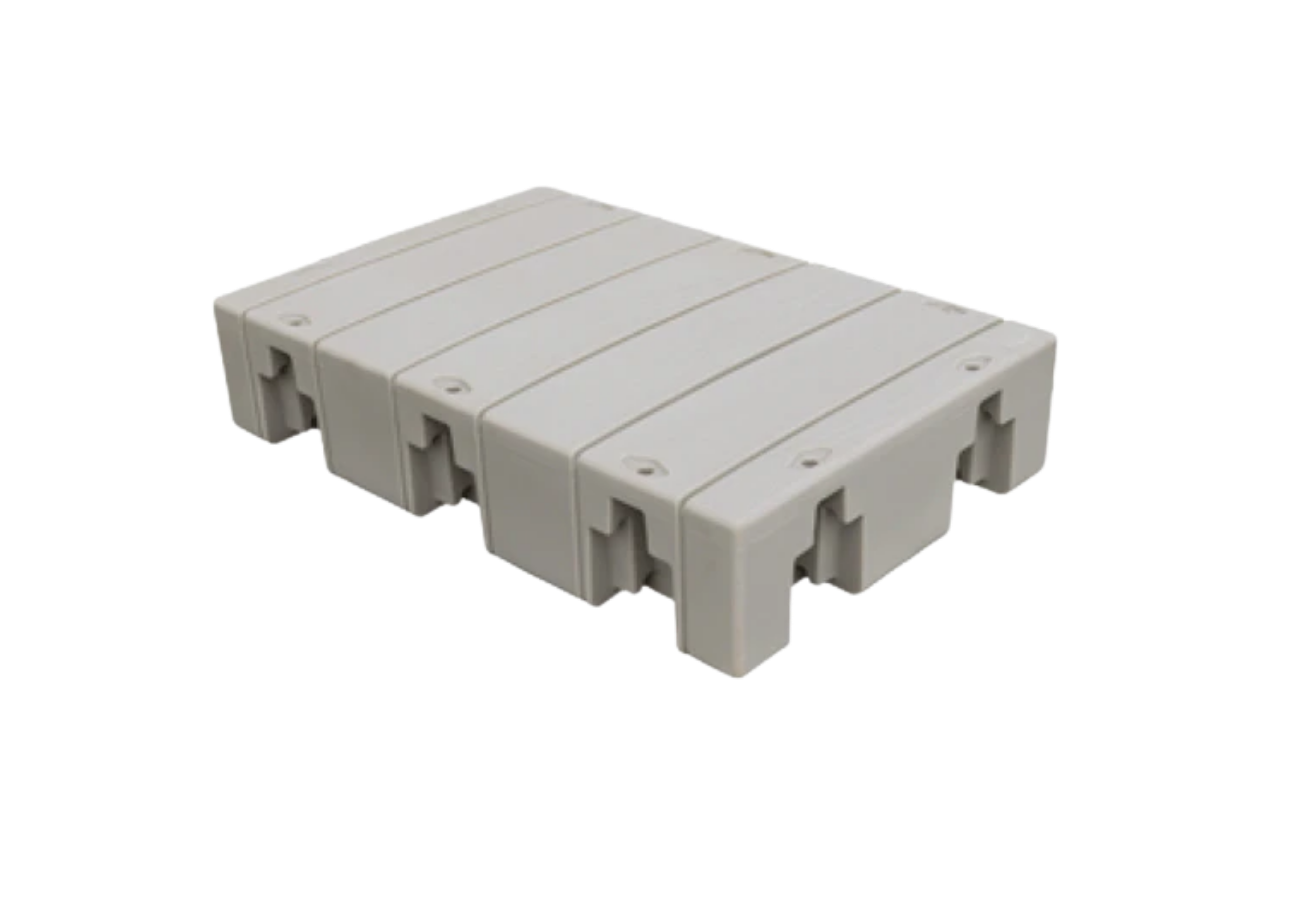

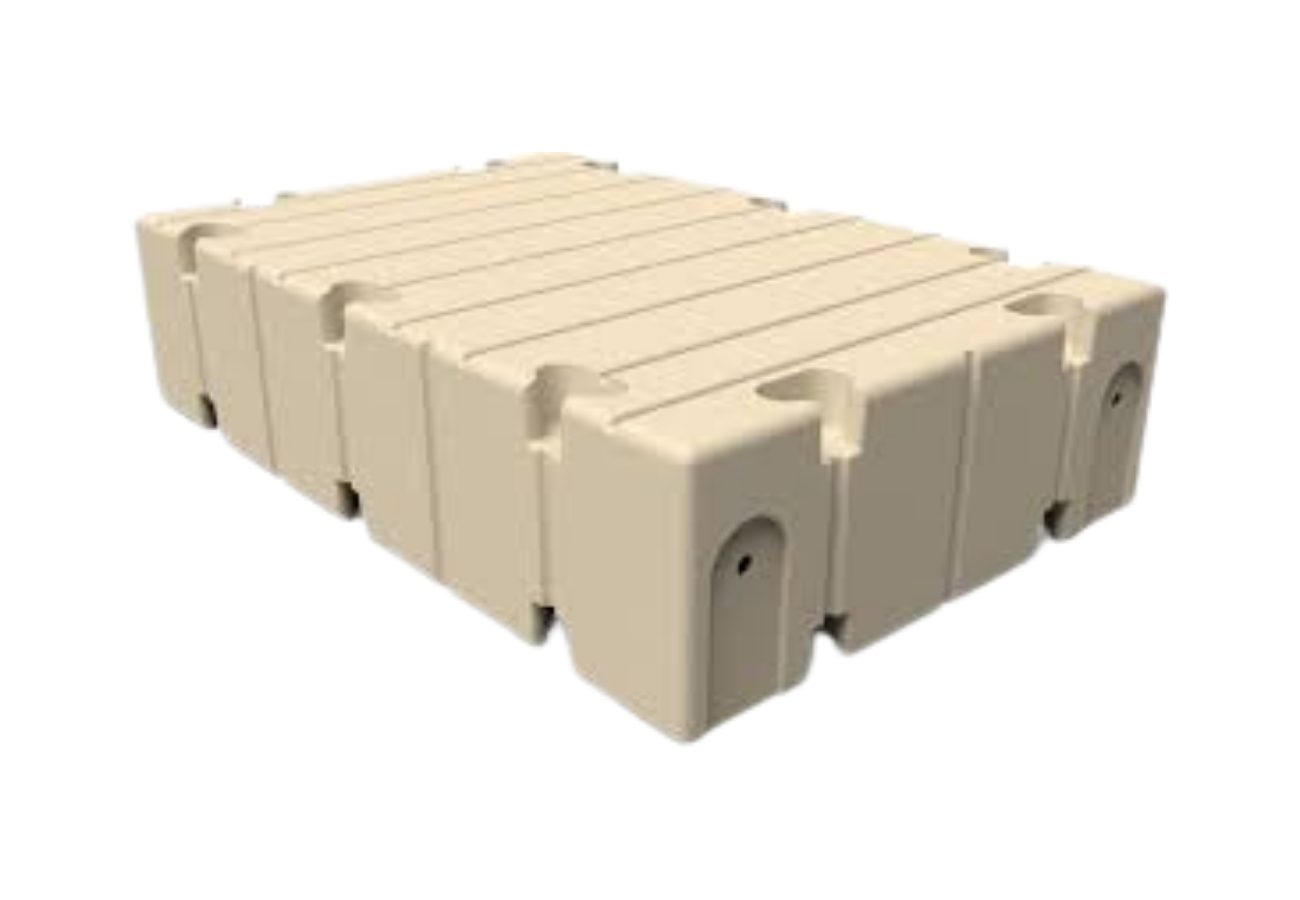

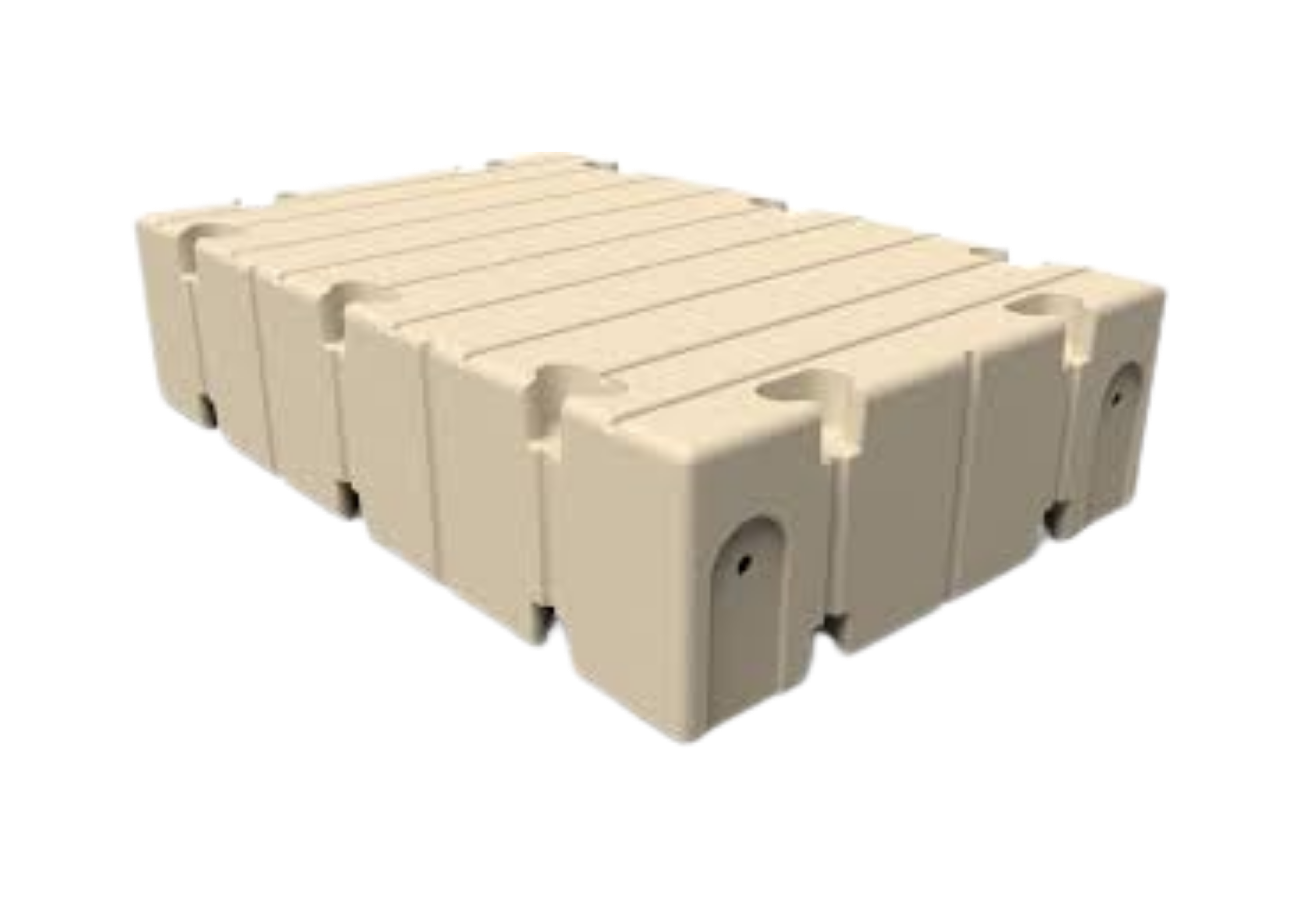

Most Polyethylene floating docks integrate their flotation into the dock platform. Some are single-unit (self contained) like EZ Dock, while others use a combination (two-piece) unit like Wave-Armor. The majority of plastic floating docks are constructed using:

HDPE (High Density Polyethylene) or

LLDPE (Linear Low Density Polyethylene)

Plastic (Polyethylene) floating docks float using either hollow cavities with trapped air, EPS (Expanded Polystyrene), or both. This is dependent on the dock design and how it is meant to float. Floating docks with cavities (trapped air) leverage the suction force known as (hydro-static) surface pressure that occurs when placed in water. This flotation dynamic is the most secure water stance due to the powerful suction the air cavities create.

Floating

Dock

Systems

Takeaways

Floating Dock technology has come a long way, and it continues to make strides to address the toughest on-water challenges.

It’s no longer a question of can a floating dock do this..

.. and more of a, which one is best!